Broken Alternator Mounting Bolt

Joe Angell

I noticed a squeaking sound coming from the alternator. It varied with engine speed and seemed to be coming from the passenger side, so that was a reasonable guess for the source. When I opened the engine cover, I found that the mounting bolt was hanging out over the belt, and the head was rubbing against it, hence the squeaking. I thought the nut had fallen off, but it was still clearly visible on the other end of the mount.

The alternator is clearly tilted and no longer aligned with the rest of the pulleys.

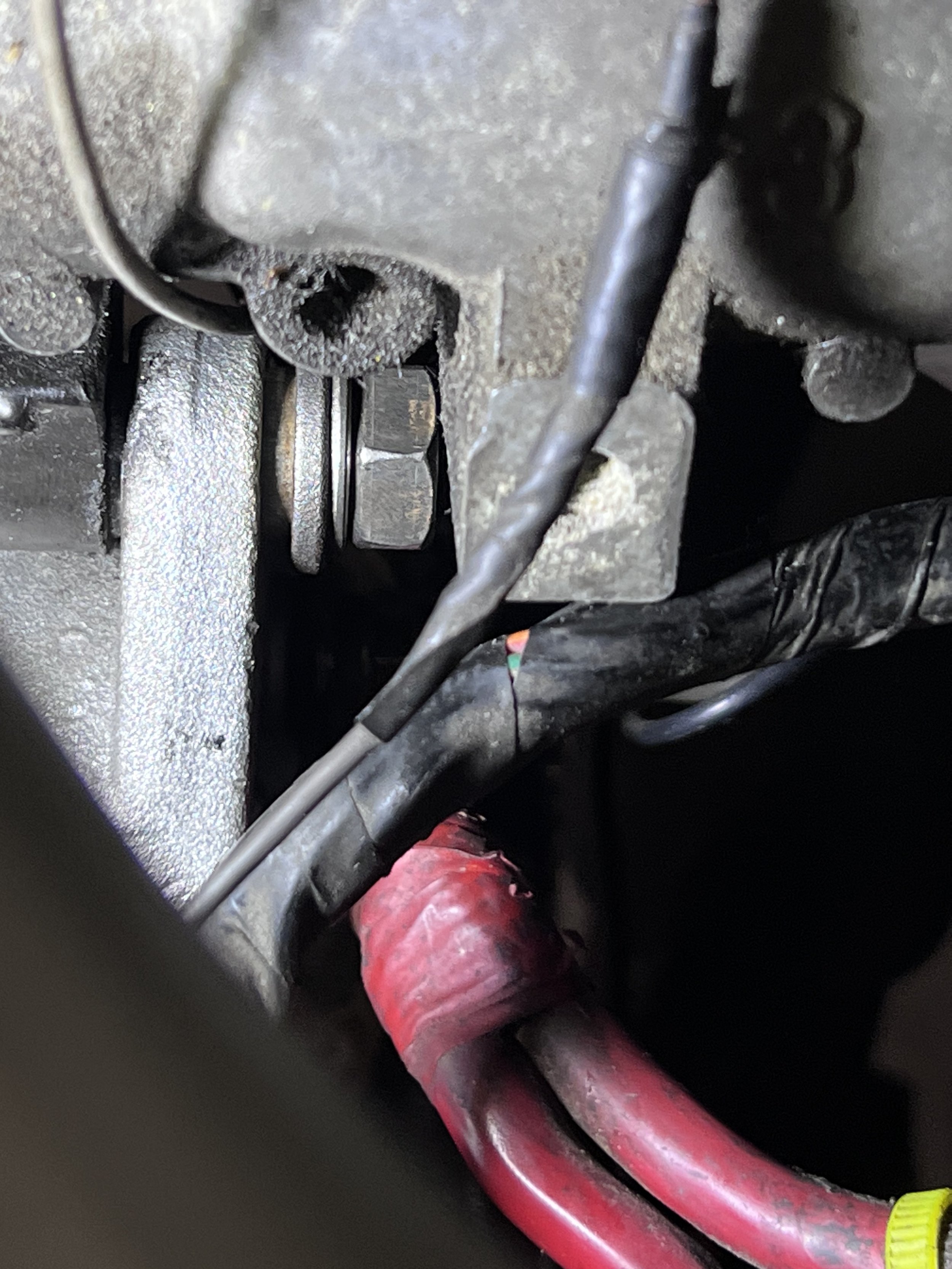

The bolt is most of the way out of the alternator, and the head was rubbing against the belt. The nut can still be seen on the other end.

It seems the bolt had snapped in half. One end was still in the mount. If it had fallen further I likely would have thrown the belt, and possibly shorted the electrical system and melted wires if they came in contact with the exhaust. The tensioning bracket would have kept it from falling out of the car or bouncing around too much, but it still would have done some damage.

The broken bolt. Not sure how that happened.

I tried to find a replacement bolt at Home Depot, but they didn’t have a 130mm M10. the best I could find was a fully-threaded 3/8” x 5”. It sort of worked, but once tensioned the alternator didn’t sit in the same place as the other pulleys, and the belt probably wouldn’t last too long.

I needed to get some more general hardware anyway, so I placed a McMaster-Carr order for grade 10 M10 bolts. Grade 10 is probably overkill, but it won’t hurt. Vendors sell both steel and stainless versions of this bolt, but McMaster-Carr gets things to me generally next day. Admittedly, each box of five bolts was $11, plus the nylocks, which didn’t come until two days later for some reason.

I ordered both 125mm and 130mm bolts. I tried the shorter one first, which worked, but I wanted more threads at the end of the bolt after the nut was on, so I switched to the 130mm bolt.

This is also when I realized that the “spacer” or whatever it is that come on the new Camero alternator was actually important. I had removed it because it interfered with mounting, but the correct solution was to turn it around and tap it back in the other way. This ensures that the hole is the correct size for the bolt and that the pulley is in the right place.

Of course, the alternator was already wired up, but I still had the spacer, so I awkwardly tapped it back in with a brass hammer from the engine bay. I then ran the bolt through and put an M10 nut on the end (I replaced it with a nylock when they arrived), tensioned the belt, and torqued everything down. The spacer was pulled in further as I tightened the nut on the bolt, creating a nice clamp to lock the alternator into place against the mount.

I fired the car up, and the newly-mounted alternator has been working fine since.

The alternator fully installed with the new bolt.

The spacer can be seen under the nut near the top of the photo. The small gap is due to the spacer being longer than the alternator mount. It’s not clear to me what this does in the Camero.