Removing the Engine and Transmission

Joe Angell

Part of the prep work for doing my EFI conversion was to remove the intake manifold to get access to the sensors in the "Y" pipe. I'd taken off this off previously when I had the cylinder heads resurfaced, replaced the exhaust, and so on, so this wasn't too much trouble.

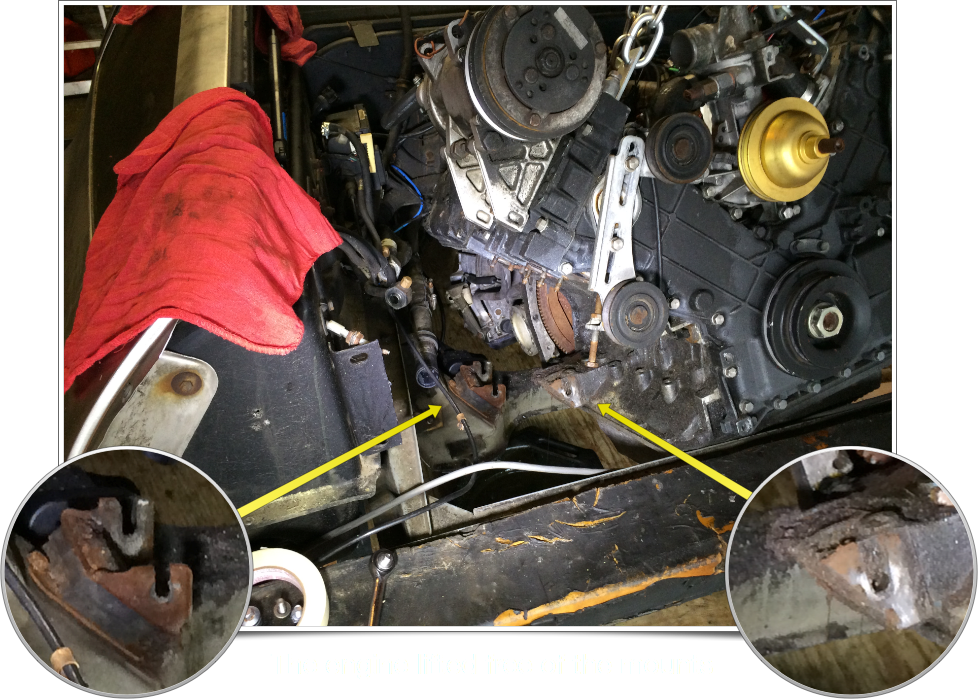

Once I removed the manifold, though, I noticed oil had collected in the valley. This is quite bad, since oil shouldn't be able to get there. I took some pictures and posted to DMCTalk, and then went about cleaning the valley. As I cleaned out more than an inch of dried oil from one of the smaller rectangular areas with a pick, I found a hole easily big enough to fit a pencil through. Holes in the valley (aka the "valley of death", or "VOD") are known as "block rot", and seem to form when coolant is left sitting on top of the aluminum block. Usually they're small pinholes that allows oil to seep out of the block; this one was quite large be comparison.

Luckily, the hole wasn't in the oil galley, which is a nearby high-pressure area that would have sprayed oil everywhere and would not be repairable (people have tried welding patches, but they tend to fail after a year or two). This hole was over the crank area, and Dave Swingle at DeLorean Midwest suggests that the oil may be from the crankshaft counterweights flinging it up into the valley. In any case, debris has obviously fallen into the hole form the engine, and Dave suggested that I take apart the engine to clean the crank bearings of debris.

I had a few options at this point:

- Buy a new engine from one of the DeLorean vendors. As of October 2013, this is about $9300.

- Buy a used engine. I was contacted by another DMCTalk member with one available for a quarter the price of one from DeLorean. It had a few more miles on it as my engine (about 93,000), but was well cared for and included the fuel and ignition components, which I could sell to recoup some of the costs.

- Clean up and fix my engine. This means disassembling it, cleaning it, replacing any worn parts, and finding someone to weld a patch on the block -- assuming there are no other weaknesses in it, that is.

- Upgrade to a 3.0L Dodge Monaco/Eagle Premiere engine. These are relatively easy to find, and usually go for under $300. This requires swapping the bottom of the DMC's B28F engine to the Dodge/Eagle engine so that it can be mounted properly, but otherwise it bolts right up to the transmission, cooling and heating systems. You also have to set up your own fuel and ignition, but I was going to do this anyway for an EFI conversion, and the 3.0L PRV already has fuel rails and a fuel pressure regulator.

No matter what I did, the first step was going to be getting the engine out of the car. After some more discussion on DMCTalk, I decided to pull the transmission and engine together.

Disclaimer

This is written from my experience of having never done this before. As such, it is not necessarily complete, nor is it necessarily the best practices, but I try to be careful and provide as much detail as I can. I am a hobbyist, not professional mechanic. My car is modified, and may not be the same as yours (exhaust, starter, automatic vs. manual transmission, etc). You should be comfortable doing this kind of work before you proceed, an be aware that 700 pounds of engine and transmission are extremely dangerous and can kill you if improperly handled. I take no responsibility for any harm to anyone or anything as a result of this guide.

This guide was written over a period of months; I'd do some work on the car about one day a week, for about 3-6 hours, and then write up what I did. Since I already had some of the fuel system components disconnected for an EFI conversion, some of the earlier steps are missing.

Special Tools

Besides the standard workshop tools of wrenches, screwdrivers, jacks and jack stands, I also needed some specialty tools to actually remove the 700 pounds of engine and transmission from the car.

Creeper (left), high lift, low-profile jack (bottom left), 2 ton folding engine hoist (right, grey) and 1000 lb engine stand (right, red).

- Engine Hoist. This is needed to actually remove the engine from the car. I went with a 2-ton hoist from Harbor Freight Tools. It on sale for was $180, which was the same or better than I could find on eBay or Amazon, and I didn't have to worry about shipping. While a 1-ton hoist would have been fine, I wasn't sure how far I'd have to extend the arm to reach the engine, and at maximum extension the capacity of the is only 1/4 of its rated weight, and I decided to err on the side of overkill.

- Engine Leveler. This is attached to the hook on the end of the engine hoist, and has four chains coming off of it that attach to the engine. A crank allows you to adjust the center of gravity of the leveler, thus allowing you to tilt the engine. This capability was important as the engine needed to be tilted so that it and the transmission could clear the bumper as they are removed from the car.

- Engine Stand. Again Harbor Freight Tools had a good deal on a 1000 lb engine stand. They had a cheaper 750 lb three-wheels stand, but I wanted to have the fourth wheel for stability. It was about $60.

- While I already had two floor jacks, I didn't have one that could lift the car from the ground all the way up to the top of two stacked pallets at once -- I had to first lift the car part way with the low-profile jack, and then the rest of the way with the high-lift jack. Both also required quite a lot of pumps to raise or lower the car. I purchased a new low-profile, high-lift fast-rise jack, which raised the car higher and required fewer pumps than either of my other jacks.

I also needed some extra wood to lay the engine and transmission on after it was removed. I was able to use one of my unused pallets while I separated the engine from the transmission, after which I could hoist the engine and mount it on the stand. Later I wound up just laying the engine and transmission on the plywood I'd laid down on the floor to provide a smoother rolling surface.

Working Room and Workspace Prep

The engine hoist is about six feet long, and needs to extend under the car. The engine and transmission are another four feet long or so. This means you need between eight and ten feet behind the car to pull an engine. Luckily, with the car pushed all the way to the end of the garage I had over nine feet of space.

The next issue was the quality of the garage floor. Since I'll be lifting around 700 pounds of engine and transmission, I needed a smooth working surface to roll the hoist around on. My garage was over a hundred years old, and featured a rather broken slate. To work around this problem, I bought some plywood from Home Depot and laid it down to create a smooth surface to roll the engine hoist on. I also made sure to get enough to slide under the car, as the legs of the engine hoist would need to fit under there to lift the engine. This mostly worked; the wood flexed a moderate amount due to inch or more depressions in the floor, so I wound up reinforcing those areas with flat pieces of wood. I still needed to be careful moving the hoist between to sheets of wood, although screwing them together on the edges did help ensure that the boards didn't separate while rolling.

Removing the Rear Fascia

The first step is to take the fascia off the car. I already had the rear of the car raised on pallets I'd constructed from 2x4s to make it easier to get under the car. Taking off the fascia removes two pieces (in addition to the tail lights and the license plate holder): the fascia itself, and the backing that the fascia mounts to.

- Remove the four (4) philips screws holding the license plate carrier and remove it.

- Remove the twelve (12) philips screws holding the tail lights (six per assembly) onto the fascia and remove the assemblies from the car.

- Remove the nine (9) M6 nuts from the underside the fascia with a 10mm socket. All of my studs had broken the last time I took this off, and after failing to successfully attach new studs I gave up and drilled holes for stainless bolts and nuts.

- Remove the seven (7) philips screws from the inside top of the fascia.

- Remove the four (4) bolts (two on each side) holding the fascia brackets to the body. You can do this from the engine bay or from the fascia; whichever is more convenient.

- Remove the six (6) M6 bolts (three on each side) holding the inner fascia to the backing with a 10mm socket with a tilt head or a socket driver.

- Unplug the black bulkhead connector and pull it through the engine bay to the fascia. This handles all the wiring for the tail lights, license plate lights and rear side marker lights.

- At this point you should remove the rear side marker lights and disconnect them from the wiring harness. I order to avoid doing this at some point in the past, I'd cut the marker light wires inside the tail light area and added blade-style connectors, so I simply disconnected those instead.

- Disconnect any high-center stop light you may have installed, and any other wiring you might have added (I had a HCSL and backup sensors.

- Remove the two (2) screws (one on each side) behind the taillight areas that were holding the backing to the body. These were clearly an aftermarket addition in my car, and it is apparently common to see something like this in DeLoreans.

- Separate the fascia from the backing. You can can now remove the fascia from the car completely once you run the wiring harness through the hole in the backing and unplug the license plate lights; however, the license plate lights are rather hard to get to, so I kept my backing and fascia together together and removed them at the same time.

- Remove the two (2) M6 bolts securing the engine cover latch to the backing with a 10mm socket.

- Disconnect the latch linkage and set the latch aside. The linkage will still be connected through the firewall to the release handle; just set it aside.

- Remove the backing from the car.

Removing the Engine Cover and Louvers

To get the engine hoist in there, you'll need to remove the engine cover and louvers. This is pretty straight forward:

- Prop the engine cover open with a piece of wood.

- Remove the two bolts holding the engine cover support to the back wall of the engine bay.

- Remove the four M6 nuts (two per side) holding the hinges to the engine cover with a 10mm socket.

- Remove the engine cover for the car.

- Prop open the louvers with a piece of wood.

- Use a 13mm socket to remove the two nuts (one per side) securing the lift struts to the louvers. I didn't remove the struts themselves from the car, instead leaving them attached to the quarter panel.

- Use a 13mm socket to remove the four nuts (two per side) holding the louvers to the hinges. The bolts and associated carrier come out together,.

- Disconnect any high center stop light you may have installed. I had to remove the trim (which is held in place with three philips screws) just under the T panel to get at the wires to do so.

- Remove the louvers from the car.

Removing the Exhaust

Next you'll need to remove the exhaust. I have a DeLorean Performance Industries SPEC I exhaust, so how I removed mine may be different from how you removed yours. I first removed the six (6) bolts (three on each side) that connected the headers to the exhaust. I then had to remove the three exhaust brackets, and then removed the twenty-four (24) nuts (twelve on each side in my case, although six per side is standard) holding the headers to the exhaust studs on the cylinder heads. I was hoping to leave the headers on, but with the exhaust out it became clear that they would still interfere with lifting the engine out of the bay.

I also had to take out the engine's oil dipstick tube to remove the driver's side exhaust header. This required removing an M7 bolt on the driver's side of the cylinder head with an 11mm socket, and then pulling and twisting the filler tube to free it form the engine itself.

Disconnecting the Wiring Harnesses

Since I was prepping for EFI, I had already removed many of the old fuel system components, including the intake manifold, cold start valve, control pressure regulator (aka warm-up regulator), fuel distributor, fuel injectors and intake manifold. All of these modules could have simply remained on the engine if I was simply pulling it.

The wiring harnesses are most easily disconnected from the bulkhead connectors on the passenger side firewall. I had already disconnected many of the connectors as I'd removed fuel system components, but it was simpler to finish by disconnecting the bulkhead connectors directly. I left only the top-rear two connectors plugged in.

You'll also need to disconnect the heavy red wires between the electrical system, the alternator and the starter. I also unplugged the alternator's sender wire.

Disconnecting the Vacuum Lines

There are two lines on the back of the intake manifold (one on the driver's side and one on the passenger side) that have to come out. There are also vacuum lines on the driver's side of the engine that go into the charcoal canister inside the driver's side pontoon that have to be removed. Most of the lines simply pull out of their barb fittings, although the ones on the back of the intake manifold are removed with a wrench.

Removing Engine Accessories

The air conditioning compressor needs to be removed, or at least moved out of the way. If you're A/C system is empty like mine was (it had a leak) and is already exposed to air, you can just disconnect the hoses from the compressor by removing the single large bolt between the hoses. If not, you'll want to remove the compressor itself from the engine and set it aside so that it won't interfere with removing the engine. Either way you'll need to first remove the belt by loosening the very long tensioning bolt. This points upward, and is under the driver's side of the engine; it pulls the the idler pulleys outward to tighten the belt. The compressor is held down with four (4) bolts requiring a 14mm socket to remove. You'll also need to unplug the wire on the compressor that engages the clutch.

While I was removing the exhaust, I also removed the alternator. This also made it easier to disconnect the heavy red power leads between it, the starter and the battery.

Disconnecting the Coolant Hoses

Before taking off the "Y" pipe, I attempted to drain the coolant from the car at the bleeder on the radiator while the back of the car was raised. This got out more than a gallon, but didn't get it all -- I wound up pumping another gallon or so out of the valley as it leaked out of the "Y" pipe. I should have checked the workshop manual first; it mentions a coolant drain plug on the bottom passenger side of the engine, just above the oil filter. This plug requires an 8mm square drive wrench, which is the same as the oil pan. Be prepared for the coolant to spill farther to the right than you might expect, and you'll want to make sure the car is level or nose-up before draining. This got another half gallon or so of coolant out of the engine block.

Later, while learning down the 2.8L engine, I discovered that there are two plugs on the sides of the block that are specifically for draining the coolant. These are towards the pulley side of the engine, one on each side, near the bottom of where the cylinders sit in the block, just above the oil filter. They require the same 8mm square drive used on the oil pan. I would have gotten much more coolant out if I'd noticed these earlier, and probably made much less of a mess.

After that, I was able to disconnect the coolant hoses from the sides of the water pump by removing the hose clamps. A pick and hook set can help get stubborn hoses off by allowing you to pry under them and tug them back. I completely removed those hoses from the car to make sure the engine could be lifted out cleanly.

Normally you'd also have to disconnect the heater hoses from the back of the engine. Since I had removed the "Y" pipe and the heater pipe underneath it, I already had this covered.

I did notice a hose attached to the driver's side cylinder head just below the distributor. This had a 'T' junction that lead under the car and to the coolant bottle. I disconnected it at the 'T' on the cylinder head side. This is held in place with hose clamps, just like the other coolant hoses.

Disconnecting the Throttle Linkage

The throttle needs to be disconnected before the engine can be removed. I decided to just unmount the throttle spool from the engine by removing the three (3) M7 bolts that held int into places with an 11mm wrench. I then removed the clip that held the adjustable throttle arm to the throttles on the "W" pipe, popped off the arm, and replaced the clip so that I wouldn't lose it.

Disconnecting the Transmission (Automatic)

The transmission is attached to the wheels via the transaxles, the shifter linkage, coolant lines and the computer wiring harness. Also, the parking brake cable needs to be disconnected so the transmission can clear it.

Transaxles

There are six (6) large bolts on each axle (twelve (12) total) at the transmission that are removed with a 17mm wrench. The bolts are so close to the link arm's flexible shaft cover that you'll need to use an open ended wrench for this; a socket will barely fit, but it's not worth the trouble. After removing two bolts, you'll need to put the car in neutral and rotate the tire 120 degrees to get to the next set. Under each pair of bolts is a curved metal shim that should be kept and reinstalled with the bolts during assembly.

Once disconnected, the axles will hang down from the wheels. You're not supposed to let them hang, but rather support them from with jack stands or tie them up with rope, zip ties, bungee cords, etc. I, not knowing this, let them hang before I eventually disconnected them from the wheels later on.

Transmission Oil Cooler

I choose to drain the transmission fluid, which is done by removing the drain plug with an 8mm squared drive socket on the pan. I did not drain the final drive fluid. Once drained, I disconnected the transmission's oil cooler line from the transmission, using an 18mm flare wrench on the forward connection and a 19mm crows foot wrench on a long extension with a socket wrench for the rear connection. These are located on the passenger side of the car, and are a J-shaped hard line going connected to short soft lines from the transmission to the main coolant return line. That rear one was quite a pain to get to, and after I broke it loose I wound up reaching over the top of the transmission with a 19mm open end wrench to finish removing it. Once it was completely unscrewed, it still "stuck" and I had to popped off with some upward force.

Wiring Harness

Back in the engine bay, I opened up the automatic transmission wiring harness cover so that I could unplug the two large connectors within. This is located on the firewall under the rear window, towards the driver's side of the car, to the left of the transmission dipstick. I then used a pry bar to slide the harness off of its mount on the firewall.

Shift Linkage

Under the car again, I needed to disconnect the shift linkage from the transmission. This is found in the square hole forward of the transmission, near the fuel accumulator. I first put the shifter into '1' so that I could more easily reach the nut on top of the pivot arm, which I removed with a 13mm socket and a short socket wrench. The linkage is pretty firmly snapped onto the pivot, and required a bit of force to pop it off.

The linkage is also held against the frame via a bracket, which is held in place by two bolts. The are removed with a 10mm socket socket. In most cars, the nuts for those bolts are welded to the frame, but in my early VIN they are not. I had to use my phone's camera to get a good view of them in the gap between the frame and the fiberglass body. I spent a couple of hours trying to squeeze my 10mm open ended wrench between the frame and body to slip it onto the nuts, sometimes guiding it with my phone camera, and then was able to turn the bolts with the socket wrench. While this finally worked, but I have no idea how I'm getting those nuts back in there.

Throttle Linkage

The transmission is also connected to the throttle spool via a cable. This is easily removed at the spool by pulling the wire out to the side, and then sliding the cylindrical end bit upward to release it from the housing.

Parking Brake Cable

I also had to remove a couple of zip ties that secured some unrelated wires and hoses to the transmission. These were easily cut off. Some of those ties were securing the parking brake cable that runs to the passenger side rear wheel. The workshop manual suggests removing this as well to keep it from being snagged while pulling the transmission.

I took off the tire and soaked the rusted hardware with Kroil first. Removing the nut that holds the end of the cable to the caliper with a 10mm wrench was straight forward. Getting the cable off of the hub carrier wasn't as obvious. There are a couple of options here:

- Remove the large nut securing the upper link arm bolt (which also holds the parking brake bracket to the hub carrier), and then remove the philips screw underneath.

- Remove the parking brake cable from the bracket.

I decided on the latter. This was more difficult than expected, and I created a thread on DMCTalk to get help. What you have to do is back off the nut closest to the caliper all the way with a 15mm wrench. It can be tough to tell when it's all the way off, as the spring keeps tension on it. I also used a 14mm wrench to hold the nut on the other side of the bracket, but this wasn't really necessary. Once removed, you grab and pull the other end of the cable towards the center of the car. This compresses washers and nuts against the spring, revealing the cable itself. You can then slip the cable out through the slot in the bracket, and the move the cable itself towards the driver's side of the car so that it is out of the way of the transmission.

Unbolting the Transmission Mounts

There are two bolts holding the transmission to the mounts, one on each side. They are annoyingly recessed and difficult to get to. I couldn't find a wrench that was quite right; sockets were either took short, too long, or the socket wrench head was too big, a 90 degree offset wrench wasn't long enough, and a standard wrench was far too short to reach over the flange.

I finally hit on using a 17mm socket with a square drive socket cap adaptor plugged into it. I found a set of these at Harbor Freight Tools and bought it on a whim. It lets you turn a socket with a standard wrench. This was just the right length to clear the flange and fit in the tight space, while still allowing me to turn it. The 12-point wrench I was using allowed me to rotate the wrench to the best point on the socket cap adaptor to be able to turn the nut a few degrees. I used an offset wrench on the bolt head, although a normal wrench probably would have worked fine. There was no friction between the bolt and the mount -- the holes line up perfectly, and the weight is taken by the mount; the bolt is just there to make sure the transmission stays put. As such, removing the bolts does not cause the transmission to drop in any way, plus the engine is still bolted firmly into place.

The driver's side was the easier one to get to; the passenger side one is basically the same, but the transmission oil cooler runs right under it, making access even more difficult. I decide to remove the oil cooler and associated coolant pipe from the car entirely. First I used 8mm socket to remove the two bolts clamping the oil cooler to its bracket. A flat head screwdriver was then used to back off the hose clamp and release it from the oil cooler, as well as the hose clamp on the 'T' in the engine bay that connects the pipe to the coolant bottle. I was then able to slip the rubber joint off the cooler and pull the entire thing out through the engine bay. With it out of the car, this also gave me a chance to straighten some of the vanes on the PJ Grady transmission heat sink that I'd added a few years back.

Of course, my the end of the coolant pipe still blocked access to the nut. It was not possible to simply push it out of the way. I needed to remove the bracket that held it and the other pipe to the frame. This was simple enough -- a 10mm socket driver and wrench easily removed the two nuts and bolts, allowing me to drop the pipe and move it off to the side. Even though I had tried to drain all the coolant from the system, a few more cups remained in the pipe, so be sure to have a pan ready to catch it.

Withe the pipes out of the way, I was finally able to remove the bolt using the same combination of 17mm offset wrench and 17mm socket/adaptor/wrench that I used on the other side.

Setting up the Engine Hoist

With the transmission mounts unbolted and everything disconnected, the only two bolts holding the engine and transmission in the car where those on the engine mount. Before disconnecting those, I needed to set up the engine hoist.

Hoist Setup

There's not much to setting up the hoist. After I assembled it per the instructions, I lowered the two foldable legs and raised the arm so that it would clear the engine bay. I then clipped the engine leveler onto the hoist's hook. The leveler has four chains that are to be attached to the engine block. Then I just had to roll the hoist under the car. The hoist has an adjustable length arm, although lengthening the arm also reduces the amount of weight it can take. This is why I got the 2 ton hoist instead, but I only needed to extend the arm out a single notch, which still allowed it to hold 1.5 tons -- enough to lift the entire car, much less the engine and transmission. Obviously you'll need the engine cover and louvers off before you can do any of this. I also lowered the car so that it was still about a half a foot off the ground, but not as high as I had it when I needed to roll under it. This makes it easier to hook up the hoist and for the lifted engine to clear the engine bay.

Hooking up the Leveler

Next the leveler has to be hooked up to the engine. The DeLorean's PRV-6 already has four rings mounted to the block (as pictured in the Worksop Manual on page C:04:03) for attaching a sling, but the L-shaped brackets on the end of my leveler's chains wouldn't really line up with the holes properly. To resolve this problem, I just removed the rings from the engine block with a 13mm socket and bolted the brackets directly to the block. To make sure the bolts fit properly in the wider bracket holes and didn't slip through, I had to use some thick, wide washers as well. It might also have been a good idea to use longer 13mm bolts, but the ones used to hold the rings in place worked fine.

The only problem I had here was actually finding the fourth lifting ring near the distributor -- it wasn't there. A quick question to DMCTalk made it clear that the ring was missing from my car for whatever reason, and that there are two holes on the forward part of the cylinder head onto which the ring normally mounts, just beyond the distributor. It was also mentioned that the engine can be (and commonly is) lifted with just two diagonally-oposed rings. I decided to just use the three mounting points, and skip the fourth.

Unbolting the Engine Mounts and Hoisting

This is where you finally hoist the engine and transmission from the car.

IMPORTANT: NEVER GET UNDER THE ENGINE, TRANSMISSION OR HOIST WHEN LIFTING THE ENGINE

The engine and transmission together weigh around 700 lbs. If the hoist fails, a chain slips, or anything like that happens, you can be seriously injured or killed. Never put anything below the engine, transmission or hoist that you want to keep, including yourself. I wouldn't even wave my hand under it.

Tensioning the Hoist

Before removing the mounting bolts, you need to tighten the hoist chains so that the engine won't fall when the bolts are removed. The idea here is to have equal tension on all the chains, and to balance it so that the weight of the engine is supported by the hoist once the bolts are removed, but not so much tension that the engine will bounce up once the bolts are pulled out.

Unbolting

Unbolting the mounts is straight-forward enough. Unlike the transmission, the engine mounts are easily accessible by sitting on the ground next to your engine hoist at the left or right side of the engine where it meets the frame.

A 17mm socket and wrench should break these free. Mine were pretty rusted, but I'd been soaking them with Kroil as I was disconnecting other things, so by the time I got to them they come out surprisingly easy. I was also surprised to find that these weren't bolts and nuts, but rather each was a rod with threaded ends and a nut on each end. The passenger side mount has a larger ground connected to it as well, of which mine was pretty green with corrosion.

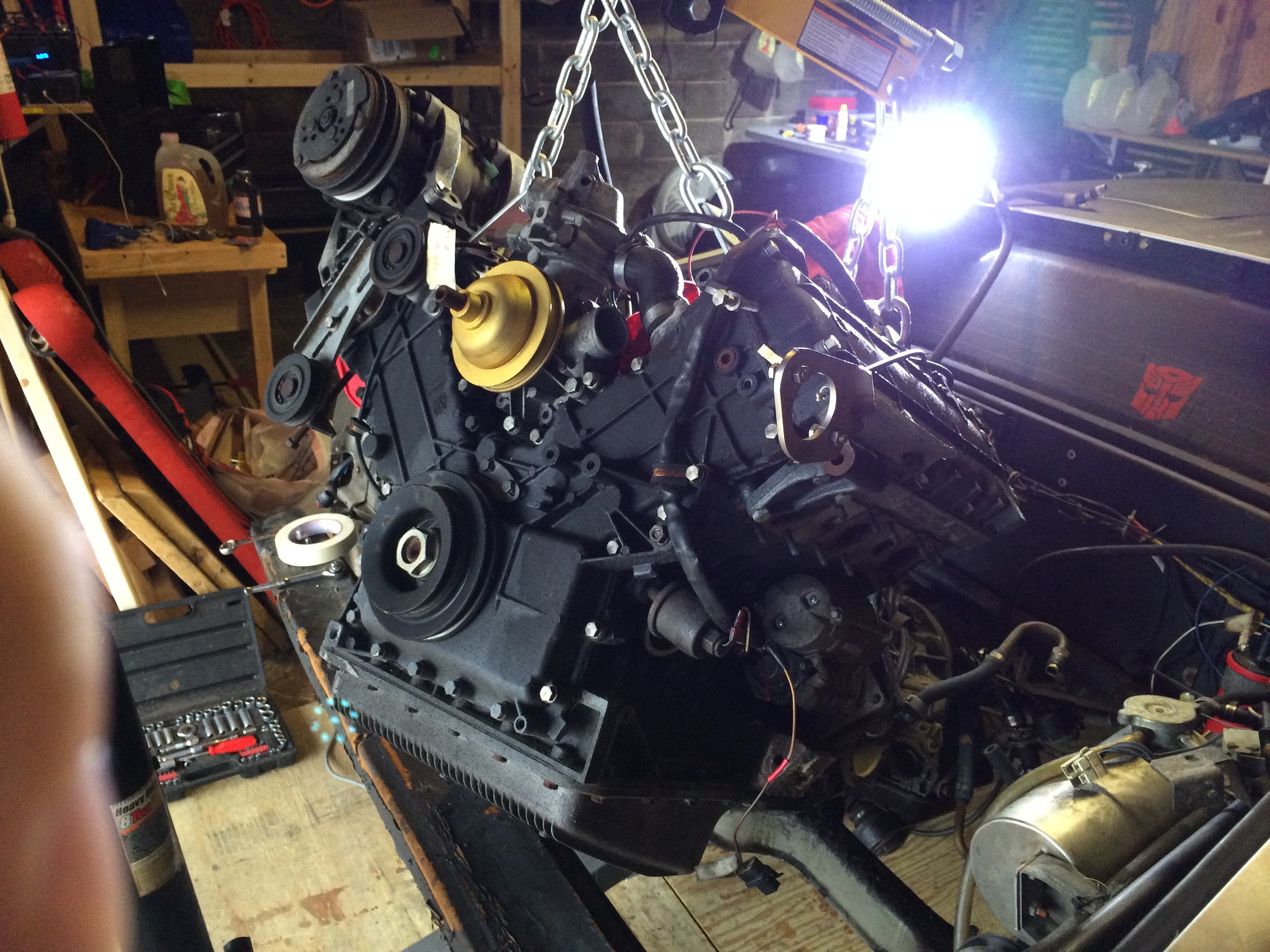

Lifting the Engine and Transmission

At this point, the the engine no longer connected to the car and the entire weight of the engine and transmission is being held by the hoist, and the fact that the engine is still sitting on the mounts.

The transmission is sitting between the frame and under the body, which means it needs to be tilted to come out of the car. I started by turning the crank on the leveler to tilt the transmission downward so that I could remove it form the car. At first nothing seemed to happen; the engine and transmission were still firmly stuck in their mounts. I raised the hoist a little, and the whole car seemed to raise -- it took me a bit to realize that this was the suspension relaxing as the weight of the engine and transmission was removed. Soon I was able to see the engine clear the mounts.

I continued to raise the engine, but did so very slowly, being careful to check for any snags in case I forgot to disconnect a hose or a wire. The hoist is powerful enough and the engine/transmission heavy enough that you could easily lift the car itself, damage wiring, bend metal and break parts if you're not careful. I did wind up forgetting to disconnect the red wire to the starter solenoid (I just cut the wire, since it had a lot of slack in, and will put a new ring terminal on it later), and I missed a zip tie that was securing one of the A/C hoses to the transmission harness for some reason.

Occasionally I would push against the engine to see if it would move freely. I'm not sure this was overly wise, as a couple of times it slipped slightly, but with the weight taken up by the hoist nothing bad happened. Since I was lifting from only three of the four lift points, the engine twisted a bit, turning the transmission towards the driver's side of the car. This wasn't a big deal, though.

Once the engine was raised high enough, I tried pulling the hoist backward so that the transmission would clear the body and the engine would start to move over the bumper. This was surprisingly difficult, even with my plywood floor. I wound up using a six foot long piece of metal pipe (which I normally use as a cheater bar to break bolts free) as a lever against the base of the hoist, inching it backwards. This worked quite well, and was much easier than throwing all my weight at it.

Due to the angle of the engine, it started dripping oil and coolant that I hadn't been able to drain before, so I put a pan under it to collect it. Th drips were from the driver's side; I believe the oil was coming from the dip stick port on the bottom of the block. I pushed the pan forward with the six foot pipe as I inched the engine and transmission upward and forward.

After the engine was high enough, I cranked the leveler to try to level the engine. It turns out the weight was still a bit too far back, and while I couldn't quite get it level, I was just barely able to clear the bumper with the hoist at maximum height and the car still raised a few inches off the ground. Once the engine and transmission had cleared the bumper, I tuned the hoist to the side and very slowly lowered the engine and transmission to the ground.

When it was about a foot from the ground, I turned the valve to stop lowering -- but I turned it the wrong way, and the engine quickly dropped on the plastic pan that I had been collecting the dripping oil with, spilling it everywhere. At least the pan kept the engine from getting damaged.

I'm told you should rest the engine and transmission on 2x4s or pallets to keep from damaging the pans or bending anything. I couldn't see a good way to do this and still keep the engine and transmission level with each other for separation, so I just rested them on the plywood I'd previously laid down on the floor to get a smooth rolling surface for the hoist.

Separating the Engine and Transmission

With the engine and transmission out of the car, I now needed to separate the two from each other.

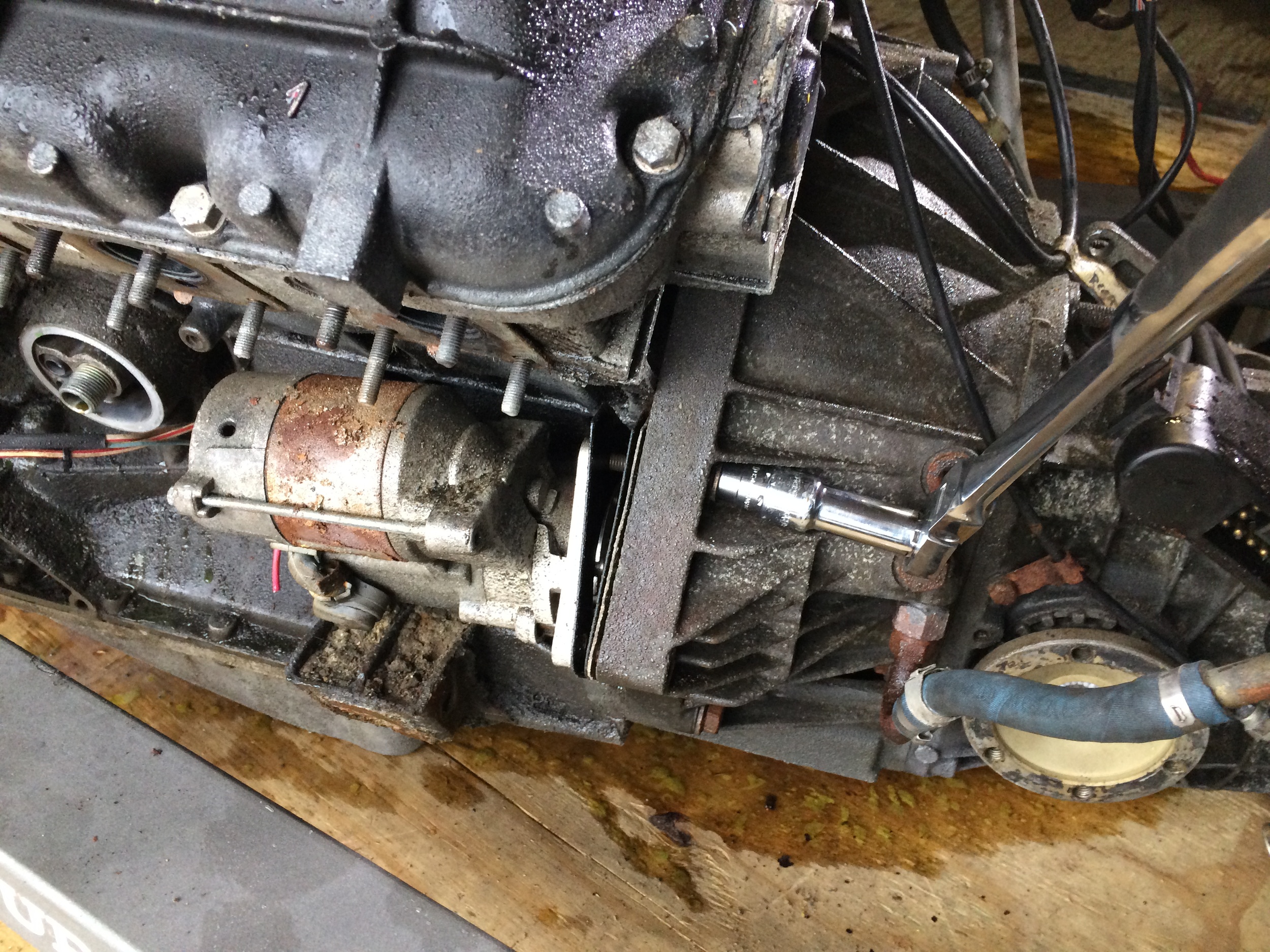

Starter

The first step was to remove the starter, as it interfaces with the flex plate on the automatic transmission and might make it difficult to separate the two (the stater turns the ring gear around the outer edge of the flex plate to spin the engine and start the car). This was a little easier outside of the car, since I didn't have to lay on my back. There are three bolts that hold it in place, and are removed with a 13mm socket with a short extension. I also had to use a small socket to disconnect the teal/yellow wire from the starter to the wiring harness. All of the other wires had been disconnected while the engine was still in the car. A shim plate sits between the starter and transmission, so that came off too. I have an after-market high-torque starter, but the process is the same for all starters.

Transmission Filler Tube

The transmission filler tub is attached to the back of the driver's side cylinder, and is easily removed with a 10mm open-end wrench. I didn't actually notice this until I'd separated the engine and transmission, and was trying to figure out why they were still connected..

Flex Plate to Torque Converter

Since I have an automatic transmission, I needed to decouple the flex plate (which is part of the engine) from the torque converter (which is part of the transmission). The workshop manual wasn't very clear about this, so I asked on DMCTalk. There are three bolts joining the two, and they are visible from the open areas on either side of the engine, such as the where the starter was mounted. There is also an inspection plate on the bottom of the transmission that is probably a lot more accessible when the transmission is in the car.

To access these bolts, you have to rotate the engine. This involves a large 35mm socket on the engine pulley. When possible, you should always rotate the engine clockwise when viewed from the pulley end, since that's the way it normally turns and engines aren't really designed to turn backwards. As you rotate it, you just look for the bolt heads on the flex plate.

In the DMCTalk thread David Teitelbaum noted that I should mark the locations of the bolts on the flex plate, as the plate is not symmetrical and it needs to be lined up exactly when reconnecting the two. While I couldn't actually mark at the bolts themselves, I was able to mark at the large gaps in the flex plate, through which the torque converter is visible. Using a silver Sharpie, I put one mark on the flex plate and another identical mark inside the gap on the torque converter. I did this at three points about 120 degrees apart, each with a different pair of symbols. I later realized hat David uses a punch to mark the flex plate and the torque converter so that the marks will be visible even after cleaning.

After marking, I kept the socket on the pulley nut and wedged the end of the wrench against against the floor. This allowed me to turn the bolt on the flex plate with a 17mm box wrench (my sockets wouldn't quite fit the space) without the torque causing the flex plate turning the engine itself. After removing one nut, I rotated the engine clockwise and did the second, and then again for the third.

Engine to Transmission

With the flex plate and torque converter bolts out of the way, I just had to remove the four large bolts joining the engine block to the transmission housing. These are arrayed in a semi-circle around the top of the transmission bell housing, and were easily removed with a 17mm socket.

Separating

Separating the two is now just a matter of pulling them apart. There are two alignment pins in the transmission bell housing. Sometimes these stick, and you may need to use a pry bar to break the engine free of the transmission.

I was also warned by David Teitelbaum that the torque convert can fall out of the transmission, and to be careful to hold it in place while separating it from the engine. The suggestion is to slip a screwdriver between the casings as you pull them apart, and push the torque converter back towards the transmission to ensure that it stays with it.

What I did was lift the engine with the hoist so that it was just off the ground, in order to reduce the friction between the engine/transmission and floor as I pulled them apart. The idea here was to still keep the engine as low as possible, so that the transmission wouldn't fall far (if at all) when the two were separated, but by suspending the engine slightly it would require less force to break the two free. I slid a pry bar inside the opening where the starter was mounted, between the flex plate and the torque converter, and gently pried them apart. Since my transmission was only about four years old, it wasn't as stuck in place as an older one might have been, and it easily slide apart from the engine; if I had a more tightly stuck transmission I likely would have pried against the engine block and transmission casing to avoid damaging the flex plate or torque converter, with a screwdriver or similar to hold the torque converter against the transmission. Even so, I did notice that the torque converter seemed to stick on the shaft in the center of the flex plate; if I hadn't used the pry bar to push the converter back, it's quite possible that it would have stayed with the engine and spilled transmission fluid everywhere.

With the transmission lying on the floor, it's pretty easy to push it around with your foot. I was doing this on plywood, so I didn't have to worry about scraping the metal against a concrete floor.

Mounting on the Engine Stand

With the engine and transmission separated, it was time to mount the engine on the stand . The idea is that you hoist the engine up and reuse the engine to transmission mating bolts through the holes in the arms of the engine stand to secure the engine. In practice, the DeLorean's 50mm M10 x 1.5 bolts are too short for this. After a failing to find longer bolts at a few hardware and autoparts stores, I gave up and ordered some 70mm ones from McMaster-Carr.

With the engine still on the ground, I cranked the leveler back so that the engine was more or less level. Since I was holding the engine with only three of the four anchors, it still hung around a somewhat odd angles, but it was mostly level. I was only able to mount three of the four stand fingers to the engine -- the bottom transmission mounting holts were so widely spaced that the fingers couldn't reach both of them, so I elected to only use three bolts to hold the engine to the stand. After these were in place, I tightened the bolts on the fingers to keep them from shifting. Only after tightening all the bolts did I disconnect the leveler from the engine.

While the above sounds simple enough, I had various minor issues getting things lined up. Once I had it on the stand, I realized it was tilted at ~20 degrees. I put some wood on a jack to raise it up a bit and level it while I tightened down the bolts again.

In theory you can pull the pin out of the top of the stand's mount to flip the engine around to work on the sides and bottom more easily. In practice, I found it very hard to even rotate it at all, and decided not to press my luck; it's resting upright until I need to remove the lower crankcase for the 3.0L swap.